To operate in a safe and profitable way, with social and environmental responsibility, in local and international markets, providing products and services that meet the needs of our clients and contributing to the development of our clients and of Argentina.

To be an integrated company with a strong local and internation presence, that operates with focus on technological growth, reinvestment and social and environmental responsibility.

Wenlen SA is a company entirely formed by Argentine capitals, founded in 1976.

Since then, its offices and industrial plants are located in Bella Vista, Province of Buenos

Aires, 40km away from Buenos Aires City, with a covered area of 26,400 m2 and an overall area of 51,000 m2.

Developing equipment for the oil and gas industry, it has become a role model among the metal industry companies with the highest investments on equipment.

With economic and financial soundness based on constant no-debt earnings reinvestment plans, it keeps a high interannual growth that makes it one of the biggest companies of the sector.

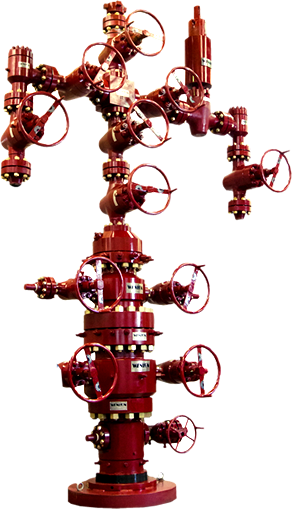

Its current manufactured line includes:

A staff of highly trained engineers and technicians continually develop new products and improve existing products using cutting-edge design, calculation and verification tools.

(CAD-3D- Solid Works- Finite Elements- etcetera).

High mechanization capacity sustained by 56 medium and high rate computarized numerical control (CNC) machines.

Owned steelmill equipped with induction furnaces to make carbon steel, alloys, stainless, Duplex and Super Duplex steel.

Electroless nickel plant: cutting-edge plant where components are nicked and thus provided anticorrosive properties, lubrication and hardness. The plant, the process and the staff are validated and certified by the main certification authorities.

Special anticorrosive painting plant: with a shot-blasting cabin where the piece receives a deep-cleaning treatment, and cutting-edge paint and gry cabin, with controlled temperature and humidity, double-filtered aire injection and cabin exit.

Clean room for the assembly of hydraulic systems according to ISO 4406 (Cleanliness rate achieved 15(14/12).

API pools for testing PLS 3 (G) omponents with high pressure gas.

High pressure, high rate hydraulic and pneumatic (nitrogen) testing equipment, in accordance to the API regulations.

Auxiliary facilities:

TAFA Thermal spray coating system PRAXAIR with ABB robot FRONIUS Clading system

Important inventory of raw materials, pieces and finished products that allows Wenlen SA to guarantee short delivery times in all its manufactured line and thus meet their clients’ needs.

After Sales Services Network covering the main countries of the Southern Cone (Argentina, Brasil, Bolivia, Peru, Chile and Colombia).

Service bases in Neuquén and Comodoro Rivadavia.